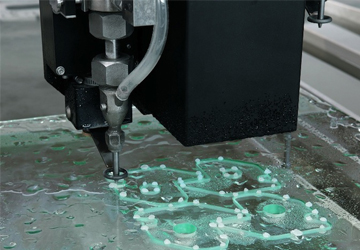

There are many advantages of waterjet cutting. As opposed to flame, plasma & laser cutting, waterjet and abrasivejet cutting produce no heat affected zone to work harden the cut edges. Therefore you are able to cut various metals, plastics and other materials without melting, distorting or warping them.

Waterjet/Abrasivejet Cutting gives us a way to routinely cut precision parts with tolerances as close as ± 0.005" and better when required. Cutting is controlled by a computer and special software which follows profiles/part geometry designed using Computer Aided Design (CAD) software.

Cut edge qualities range from Q1 to Q5. Q1 is the fastest cut and is used primarily for material separation. Depending on edge finish requirements, slower cutting speeds of Q2 through Q5 are selected. Parts requiring close tolerance geometry will of course require smoother edge finishes in that area of the part. (Note: Some other terms also used in the industry to indicate cut speed or edge quality - 100%, 80%, 60%, 40% & 20% or Fastest, Medium fast, Normal, Better & Best)

• No material deformation caused by heat

• No hardening of the material along the cut edge

• No changes to the metal structure

• No heat affected zones (HAZ)

• No hazardous fumes or vapors

• None or minimal need for reworking

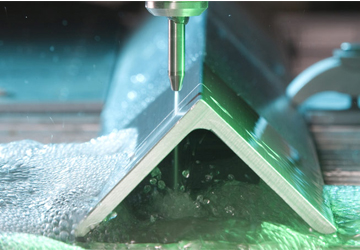

• Cut glass geometry that common machining cannot perform

• Delicate glass does not crack during processing

• Precisely cut thin to thick glass without changing any tooling

• Cuts glass panels up to 9" (23 cm) in thickness

• Eliminates pressure of cutting process on surface material

• No heat affected zone (HAZ)

• No tool to sharpen

• No or reduced need for reworking of the cut edge

• No waste of material, narrow cutting gap

• Cost effective means of cutting holes in glass

• Create intricate design in any shape and size

(Not suitable for the processing of tempered or hot glass)

Here the list of materials waterjet can perform

* Bronze

* Ceramic

* Granite

* Acrylic

* AlloysAluminum

* BaconBrass

* Broccoli

* Bronze

* CakeCarbon

* Carbon Fiber

* Cardboard

* Celery

* Ceramic

* ChickenComposites

* Copper

* Foam

* Glass

* Granite

* Granola Bars

* Inconel

* Kevlar

* Laminates

* Lettuce

* Marble

* Meat

* Paper

* Plastics

* Plexiglass

* Polycarbonate

* Polyurethane

* Porcelain

* Romaine Lettuce

* Rubber

* Stainless Steel

* Steel

* Stone

* Textiles

* Tile

* Titanium

Who are in extremely love with eco friendly system..

The mixing of abrasive particles in water jet is in such a manner that water jet’s momentum is transferred to the abrasives. • The coherent, abrasive water jet that exits the AWJM nozzle has the ability to cut various materials, such as metals, glass, ceramics and composites.

Leveraging on our revolutionary water jet cutting methodology, we facilitate our customers with cutting solutions for Mild Steel products

Our no heat CNC profile cutting process cuts any metal and non metals of any composition and type up to 150 mm thick. Just a CAD drawing will do, to bring part drawings or your ideas into reality.

This can be used to achieve intricate designs even on highly glossy and polished surfaces. In fact, using this method you can get ceramic tiles, granite, marble, slate, and limestone cut out to any of your designs. Even laminates and composites can be cut without a trace of de-lamination. In this process we can cut Acrylic, Aluminium, Brass, Carbon Steel, Ceramics, Composites, Copper, Foils, Glass, Granite, Iron, Limestone, Marble, Nylon, Plastics, PVDF, Stainless Steel, Titanium & etc.

Abrasive waterjet cutting technology is a great method for cutting glass because it allows for contours and shapes that cannot be achieved with other cutting machines at a reasonable cost. From artistic tabletop inlays to detailed stained glass designs, mirrors, glass ornaments, replacement windows for antique cars, and more, there’s almost no glass cutting application that a waterjet cutting machine from sswaterjet can’t tackle.

inappropriate behavior is often laughed off as “boys will be boys,” women face higher conduct women face higher conduct.

Waterjet cutting process cuts maximum 300mm of thickness with any materials

Waterjet cutting process works for design and fabrications

This can be used to achieve intricate designs even on highly glossy and polished surfaces. In fact, using this method you can get ceramic tiles, granite, marble, slate, and limestone cut out to any of your designs.

Because water jet cutting does not vibrate the glass and Jobs

Projects Completed

Total Employees

Happy Clients

Started Jobshop

Who are in extremely love with eco friendly system..

Accessories Here you can find the best computer accessory for your laptop, monitor, printer, scanner, speaker. Here you can find the best computer accessory for your laptop, monitor, printer, scanner, speaker.

Accessories Here you can find the best computer accessory for your laptop, monitor, printer, scanner, speaker. Here you can find the best computer accessory for your laptop, monitor, printer, scanner, speaker.

Accessories Here you can find the best computer accessory for your laptop, monitor, printer, scanner, speaker. Here you can find the best computer accessory for your laptop, monitor, printer, scanner, speaker.